The TTC Board met on April 11 with a long agenda. Among items of interest are:

- CEO’s Report

- * 2024 Asset Management Plan

- Line 3 SRT Incident Investigation and Subway Track Continuous Improvement Initiatives

- Procurement Authorization – Subway Track Rail Milling Services

- * City Council Transmittal – CC15.1 Budget Implementation Including Property Tax Rates, User Fees and Related Matters

- * Financial and Major Projects Update for the Year Ended December 31, 2023

- * Easier Access Phase III – Project Status Update April 2024

- Approval of Public Art Concepts for the Bay, Castle Frank, Christie, Donlands and Lansdowne Stations

I have already written about the SRT report, and here will discuss only the deputations and discussion at the Board meeting.

(*) Part II will review the Asset Management Plan, and Part III will cover updates on TTC finances, Major Projects and Easier Access.

A Draft Report on the TTC’s “Innovation and Sustainability Framework” was deferred to the May Board meeting, and I will comment on that when it reappears.

CEO’s Report

The CEO’s Report presentation had little to say about the current state of TTC service. This has become a typical way the report is presented.

CEO Rick Leary did mention that starting with his May 2024 report there will more issues in the “Hot Topics” section, but mentioned nothing about revising the existing metrics. Also coming with the May schedule changes will be modifications to 74 routes that are intended to improve service reliability. The details are yet to be announced, and I will post the usual wrap-up when they are revealed.

2024 Asset Management Plan

The TTC, in common with all municipalities and their agencies, is required by Provincial Regulation to produce an Asset Management Plan at the inventory level by July 1, 2024, and with projections of how it will be financed by July 1, 2025. I will cover this plan in detail in a separate article.

A major benefit of the plan’s existence is that it demonstrates the breadth of assets underlying the transit system, their importance to the whole, and the wide variation in asset quality. This provides much-needed education to Commissioners and others whose focus is too often on shiny new projects for their wards years in the future while today’s system and issues are not addressed.

After discussion, the Board decided to request the UITP (Union Internationale des Transports Publics, or International Association of Public Transport) to conduct a peer review of TTC subway and streetcar assets and maintenance programs. The scope of the review will be confirmed at the next meeting of the TTC’s Audit & Risk Management Committee currently scheduled for June 5, 2024.

Scarborough RT Derailment and Track Condition Improvement

The SRT derailment still haunts the TTC. In part this stems from the drawn-out revelations of the underlying reasons for the accident and how this has affected TTC’s attitude to maintenance in general. My previous articles are:

- The Scarborough RT Derailment Technical Reports

- The Unhappy State of SRT Track

- The State of Disrepair

- Revisionist SRT History at the TTC

- Ten Questions About the SRT Derailment

The video of deputations and debate on this item is available on YouTube.

General Impressions

Inconsistencies in the explanations advanced for the derailment include:

- At the September 2023 Board meeting, the difficulty of inspecting the integrity of bolts supporting and restraining the SRT reaction rail was repeatedly cited as a barrier to proper inspection both by TTC management and consultants. By April 2024, the official story had changed to speak of an ongoing SRT renewal program, although a key component of this that would pick up bolt failures ended in 2021.

- There was considerable hair-splitting about inspection, corrective and preventative maintenance that might or might not have occurred. One consultant, Systra Canada, stated categorically in their report that “Preventative maintenance appears to be weak or even non-existent.” At the meeting they back-pedalled about this saying that they misunderstood the relationship of capital projects to maintenance work. That story simply does not hold water as there was ample time during the finalization of their report in Fall 2023 for this to be corrected.

- The decline in the number of reported defects over recent years was explained in September as being due to a database migration and elimination of duplicate reports. In April, this decline was claimed to be the result and benefit of the renewal program.

Another key issue is the publication of consultant reports in an obscure location on the TTC’s website. TTC staff have claimed that there was notice given, but this is not true. It is now obvious from remarks by key parties, some TTC Board members and the TTC’s major union, that the availability of reports was not announced. As previously reported on this site, they came to light when I stumbled on them in January 2024 while looking for info on the Scarborough busway.

The inevitable conclusion is that management hoped that the reports would not be noticed. Technically, this is not withholding information from the Board, but the effect was almost the same.

At the Board meeting, there were deputations from Amalgamated Transit Union Local 113 (Marvin Alfred, president; Ian Fellows, legal counsel), and TTCRiders (Shelagh Pizey-Allen). There was also a staff presentation given by Fort Monaco, Chief Operations and Infrastructure Officer, Betty Hasserjian, Chief Safety Officer and consultant representatives.

ATU 113 Presentation

ATU’s Marvin Alfred began by talking about transit’s ongoing decline due to a chronic failure to invest in the system, but also spoke of mismanagement, and the unreliable and unsafe condition of the TTC. The SRT derailment was just a symptom of an underlying problem, he said, noting that a problem at the derailment site was reported two weeks before the incident. A further issue he raised was whether money budgeted to keep the SRT operating went unspent.

A common problem, Alfred stated, was the lack of transparency with the TTC Board, and a culture of secrecy. Past history in the 1995 Russell Hill accident led to a focus on State of Good Repair, but in 2020 there was a “near miss” at Osgoode Station between two trains that went unreported for almost a year. Other issues have come up, and Alfred argued that management prioritizes statistics and cost savings over safety.

He asked that the TTC Board direct management to prevent a further decline of the transit system, and to launch a “full and independent review of TTC safety and maintenance practices”.

Another issue that came up was the TTC’s move to one-person subway train operation (aka “OPTO”) which has been implemented on Lines 1 and 4. Needless to say, ATU 113 seeks to protect and restore two-person crews although one-person or even totally automated systems operate in many other cities. However the camera systems which allow an operator to view the entire length of their train and safely operate the doors are unreliable and poorly maintained according to ATU.

Commissioner Holyday asked about the process for reporting a health and safety issue like the cameras. Alfred replied that there is fatigue in reporting the same issue repeatedly, and that there is a cultural issue in the TTC that reports are not “heard” and acted on.

TTCRiders Presentation

Shelagh Pizey-Allen from TTCRiders spoke of the request her group has made to the Auditor General to investigate the derailment and its implications for TTC maintenance.

The April 2024 TTC report omits some key items in the consultant reports including reduction of preventative maintenance, inadequate training and experience of track patrollers and the prioritization of defect reports. Two of these had been flagged by Network Rail Consulting to the TTC in early 2023. (That report has not been published, but it is referenced in the August 2023 NRC report.) Pizey-Allen asked whether these issues were acted on by TTC management, and whether the derailment could have been prevented.

She went on to ask about the defect report two weeks before the derailment, asking what was done about it, and “where the buck stops” in responsibility for action.

Pizey-Allen also compared spending estimates for the SRT showing the changes over time in assumed closing dates for the SRT and related budgetary provisions for life extension. Until early 2021, the TTC’s plan appeared to aim for a 2022 shutdown of the SRT, and this is echoed in the Systra consultant report. The date was pushed out to mid-2023 with an increase in budgeted spending to keep the line working. Whether all of this was spent is another matter.

The political situation around the SRT is well known, and there was strong pressure to keep it operating as long as possible especially in light of the ever-lengthening delivery period for the Scarborough Subway.

Staff Presentation

Although the SRT derailment was the impetus for this presentation, a considerable part of the presentation dealt with ongoing changes in subway track maintenance. This was described as a five-year journey dating back to 2018. Many of the consultant recommendations have already been implemented.

There are a few inconsistencies here.

- Reports on the SRT investigation date from 2023, and it is impossible for them to have influenced practices over the period from 2018 onward. Are there other external reviews of TTC practices that have not been published? From Network Rail, we know that they produced one early in 2023.

- As I wrote elsewhere, the TTC had plans for an expanded subway work car fleet to bolster its maintenance capabilities. Work on this began under former CEO Andy Byford and his team, but budgetary allocations have been pushed out year by year thanks to competing priorities in the Rick Leary era.

- In spite of the many improvements listed above, the actual condition of subway track deteriorated in recent years leading to many restricted speed zones late in 2023 and early in 2024.

Although much work has been done to improve maintenance and engineering practices, a clear problem was flagged by Fort Monaco:

This incident has allowed us to discover a critical shortcoming in an asset believed to be in good overall condition when in fact it was not, and our 72-hour visual inspections alone were not sufficient to pick this up, and the consequences of not doing so could have been catastrophic. In hindsight, our reaction rail maintenance standard should have been reviewed and updated during the SRT life extension work to ensure more preventative maintenance was introduced on the reaction rail during non-revenue hours.

This is a very different stance from claims that there was no decline in maintenance. Only moments later, he claimed that the decline in reported defects was due to benefits of the life extension program including replacement of the “at risk assets” (the failing bolts) and improved asset reliability. The condition of bolts at the derailment site and other locations shows that, in fact, dangerously defective infrastructure was not repaired. It might be valid to state that there was no change in the inspection regime, but collectively these practices failed to review a key component and detect failures.

In his description of evolving subway track maintenance, Monaco showed a slide of the dashboard for Maximo, a database system adopted by the TTC to centralize and standardize its record keeping. (Page 16 of the presentation deck.) This clearly shows work order status. In their response to my FOI request for defect reports and work orders for the SRT, the TTC claimed that no work orders existed. Either they were never entered in the system, or no work was done, or the TTC withheld this information from their response.

The TTC has built a training centre for track maintenance at Wilson Yard and is very proud of this facility. Good training is commendable, but its value can be compromised if overall procedures prevent timely detection and correction of problems.

Migration of data from paper-based collection to a single database is still in progress. Monaco showed a box containing about 750 inspection sheets from one of the six TTC centres. This demonstrated the scope of a long-standing problem, but did not inspire confidence in robust record keeping. This echoes findings of the City Auditor General’s review of streetcar overhead maintenance which was limited by the need to manually search through paper records. TTC is now conducting trials of rugged notebooks for use by field staff to enter reports directly into the database without depending on transcription of paper notes.

Board Questions and Discussion

Commissioner Matlow pursued the issue of inconsistencies in description of preventative maintenance discussed earlier. In answer to a question from Matlow, Fort Monaco confirmed that visual inspection of the track took place, but not of the anchor bolts.

Commissioner Osborne asked if the problem of getting data transcribed into Maximo from paper reports was the same as the Auditor General flagged with streetcar overhead maintenance. Monaco concurred that this was the same situation. The full migration process will occur in stages over coming years, but meanwhile tracking will continue to depend on a paper-based process.

In answer to a question from Vice-Chair De Laurentiis, Monaco clarified that pro-active maintenance would replace problem bolts before failure, and that “in hindsight, where we lacked the pro-active maintenance was actually going and validating the tightness of those bolts”. He confirmed that this type of work ended in 2021, but that this was done because the 2021 asset condition assessment showed that all of the at-risk items from the 2016 and 2019 life extension program were completed.

This shows how the capital and operating aspects of state of good repair intertwine. The walking visual inspections (operating budget) did not pick up bolt defects, but the program of condition checks and asset replacement (capital budget) was stopped.

Commissioner Moise asked whether with the growing age of Line 2, is there a danger of a derailment on that route. Monaco replied that Line 2 has running rail [but no reaction rail like Line 3], and that this is constantly monitored and maintained to TTC and APTA standards. Moise also asked about using the Infrastructure Bank to help fund new subway cars if the federal government does not come through with their share. CFO Josie La Vita replied that using the Infrastructure Bank would change the financing of the car purchase because this would be a loan, not a grant. The TTC hopes to receive a federal grant to match the provincial funding.

Chair Myers asked about the unspent monies in the SRT life extension program. Management replied that this was in part because the 2021 condition assessment found the track did not require further work before the planned 2023 shutdown. Part of the LE money was intended for vehicle repair based on the original 2026 shutdown date, but vehicle problems made that long an extension unwise. $12 million of the unspent money was redirected to the SRT busway work.

Myers asked about the defect that was reported at the derailment site [“Reaction Rail Top Polish Raised 1/2 inch on the approach end”] and whether that was the cause of the derailment. The Network Rail consultant downplayed that situation.

- He claimed that only the reaction rail cap was lifted, not the entire structure. However, for this to be true, there would have to be a failure of the bolts anchoring the cap to the LIM “back iron”. No such problem was reported, and indeed the known problem was loose or broken mounting bolts for the entire reaction rail structure.

- He stated that a 1/2 inch rise (12.7 mm) was not sufficient to be dangerous. However, the Hatch consultant reports show that ideal gap is 12mm, although this can actually vary from 7.5 to 14.5 mm. This would leave little or no clearance, and attractive forces could lift a loose reaction rail even closer to passing cars.

- The same area was walked six more times between the initial report and the derailment, and there was no report of worsening or if the defect was even still there. [Note that in response to my FOI for defect reports, there is a two week gap after the initial report in which no defects were logged anywhere. This is unlike any other period.]

Here, from the TTC presentation and the Hatch consulting report, are diagrams showing the clearances for SRT vehicles and infrastructure. Note that there are two sets of bolts in the reaction rail. Small T-bolts hold the aluminum cap onto the main reaction rail back iron, and the longer mounting bolts anchor the reaction rail to the concrete slab. It is the latter bolts which failed either by deformation and fracture, or by pulling loose from the slab.

Commissioner Holyday asked about the situation at the derailment site where a segment of both the top cap and back iron had been cut out for repairs. He asked who designed this work. TTC staff replied (largely off mike in the video) that this was done by TTC engineers. That directly contradicts information in the consultant report stating that the design standard was for the gaps to overlap, not be directly above each other, so that the cap and the back iron would reinforce each other. The lack of this reinforcement made lifting of the reaction rail structure sitting on loose or broken bolts much easier.

To save readers the work of finding this information, here is the consultant’s text. [“DM” refers to the Design Manual.]

The aluminum top cap is designed to overlap the joints in the reaction rail for additional support of the reaction rail infrastructure per DM-0804-13, or bonded for continuity as noted in section 3.2.5 of the DM. At the location of the reaction rail retrofits, the joints with the aluminum cap are coincident with joints in the reaction rail frame. This results in a more severe difference between adjacent segments and exposes the ends of the laminated inductors, making it more likely that the train would snag on a loose or high segment of reaction rail.

Gannett Fleming Report at p. 30

In brief, a design standard requiring overlap already existed, and it was not followed in previous repair work at the site.

Motions

Commissioner Matlow moved:

The TTC Board requests that the City of Toronto’s Auditor General conduct an investigation into the systemic causes of the July 24, 2023 Scarborough Rapid Transit (SRT) derailment, with the scope of the investigation to include review of maintenance records, record keeping and third-party investigative reports.

Vice Chair De Laurentiis spoke of the importance of the Audit & Risk Management Committee as part of the Board’s oversight with management bringing more detailed information about funding requirements and choices. This could require expanding the size and mandate of the Committee. A key phrase was that “we should get the bad news quickly”.

Commissioner Holyday spoke of the various types of maintenance ranging from life-cycle replacement down to routine inspection for defects, and the importance of recognizing the importance of each type of activity. Investing in one activity does not mean that other types of work should not be done, he argued.

The Board approved Commissioner Matlow’s motion with no opposition.

Subway Track Rail Milling Services

An important component of track maintenance is the removal of surface defects on rails that accumulate from various factors. These include corrugations that produce noise in passing wheels, irregularities that can contribute to vehicle sway, and small cracks that could expand into track failures. For decades after the subway opened in 1954, rail grinding was performed by a converted 1915 streetcar, and later by a converted PCC train. From the 1990s onward, rail grinding was a contracted service. (Photos and history of these cars are available on Transit Toronto’s website in an article about subway works equipment.)

A different approach to rail surface maintenance is rail milling, a common practice overseas, but not in North America. As part of a plan developed starting in 2016 and included in the 2018 Capital Budget, management proposed acquisition of a rail milling car among several other additions to the work car fleet. (See The State of Disrepair and scroll down to the section on work cars.) Instead, the TTC contracted this service from Rhomberg Sersa starting in 2018.

Rail milling is a preferred approach compared to grinding because the rail can be more accurately profiled and less metal is lost to the milling process prolonging track life.

This report recommends renewing the milling contract for three years with options for two one-year extensions.

Public Art at Subway Stations

The Board approved without debate the proposed public art for five subway stations. This work is funded from the Easier Access Program budget with about 1% of the total going to art. Further details about the works are in the report.

Bay Station Cumberland Exit

Francisco-Fernando Granados: confluence

Castle Frank Station

Vivian Rosas: Earth Runs Wild

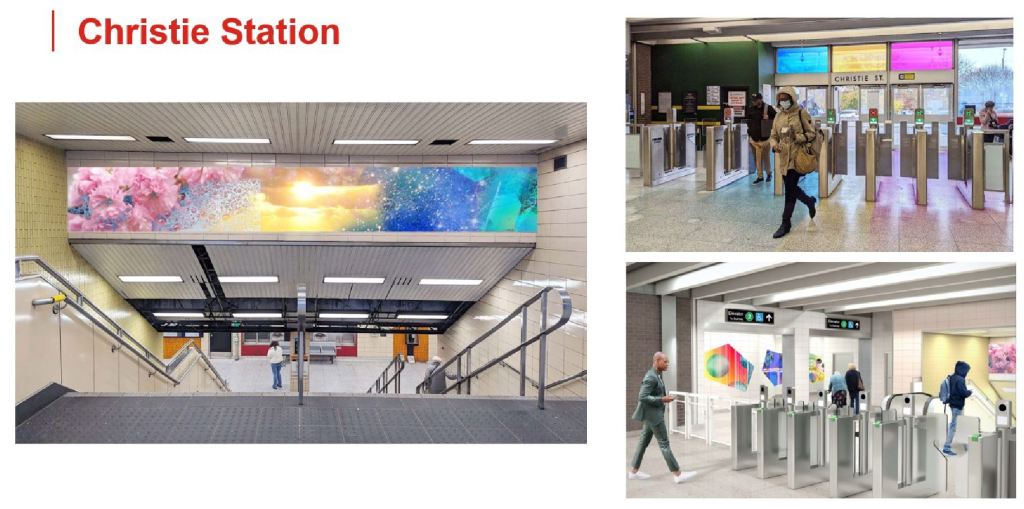

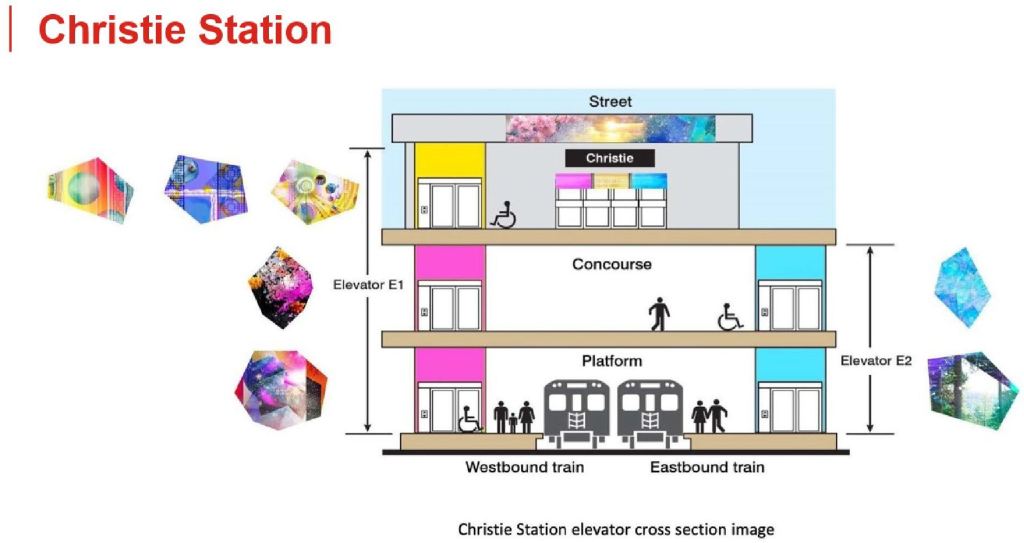

Christie Station

Sanaz Mazinani: Rise Together

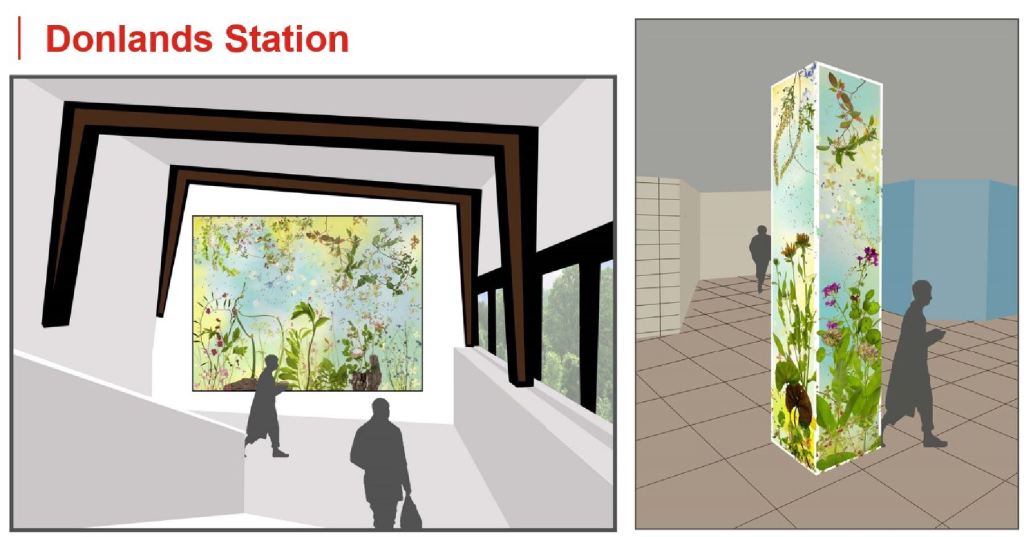

Donlands Station

April Hickox: Field

Two versions of the art are proposed. One places the image on a wall within the new secondary exit, and the other around a pillar. The wall-mounted version will be used if the space remains available.

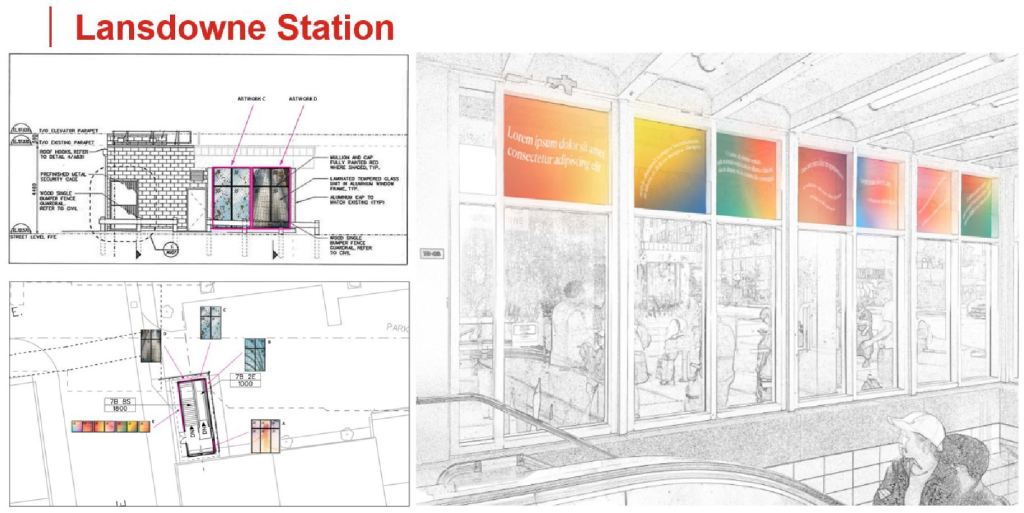

Lansdowne Station

Steven Beckly: Shifting Beauty

Talking about “art” at the subway stations, what is the status of the famous art installation at Yorkdale Station? Or is it just “talk”? Or is it “not in the budget” because it is considered “gravy”?

Steve: I believe that restoration of the Yorkdale installation was supposed to be funded externally mainly by Oxford Properties who own Yorkdale Shopping Mall.

LikeLike

The link to the Agenda – at top of article – is wrong. No doubt changed by TTC!

Steve: Yes, for some reason they have changed the date in the URL to April 18 even though the meeting was on April 11. I have updated my article. Thanks for catching this.

LikeLike

All of these art concepts are frankly hideous and if that tiny Donlands installation is 1% of the budget, we’ve vastly overpaid.

LikeLike