On April 3, 2024, the advocacy group TTCriders submitted a request to the City of Toronto Auditor General for a review of TTC maintenance practices. This arose both from the July 2023 SRT derailment and other recent events on the subway including a broken switch and a flurry of slow orders.

Full disclosure: I was asked to review a draft of the TTCriders letter and suggested minor edits, but am not a party to their request.

Both in the staff presentation at the TTC’s September 26, 2023 Board Meeting and in comments responding to TTCriders, the TTC has been quite clear that it regards the root cause of the SRT derailment to be loose mounting bolts for the reaction rail. This does not tell the full story, especially in light of consultant reports that were published well after the September 26 meeting.

The published version of the Network Rail report is dated August 23. The Hatch report is Sept 28. Gannett-Fleming’s is Oct 12. Systra’s is Nov 30. For an extensive review of these, see my previous article:

A common thread in the consultant reports was that inspection and maintenance practices were inadequate, staff were not trained in the potential danger of defects that they discovered, and many staff were juniors who had not fully qualified as track inspectors. At the time, this was treated as a problem limited to the SRT. Recent events suggest that poor practices extend beyond to the rail network generally, and this is a more pervasive problem than originally reported.

The staff presentation in September was part of a larger review of the SRT replacement service, and the report title gives no hint that the derailment is part of this. Elsewhere in the same agenda, the CEO’s report celebrates the “Farewell to the SRT” event but makes no mention of the derailment reviews.

- Line 3 Bus Replacement Update

In the TTC’s review of these reports, presented in the April 11 Board meeting agenda, these suppositions are countered, although not entirely convincingly. It is fair to assume that most people will not be familiar with the detailed reports and will take the TTC’s rebuttal at face value. [The April 11 report is discussed later in this article.]

TTC spokesperson Stuart Green said CEO Rick Leary ordered the external reports the night of the derailment to get answers on what happened while including links to the reports posted on the TTC website. He also said the matter was discussed at the Sept. 26 TTC board meeting.

“TTCriders was represented at this same meeting so presumably they heard the same information and are fully aware what the root cause was,” he wrote.

CityNews April 3, 2024

Certainly TTCriders and anyone else attending the September 26 meeting or playing the video later “heard the same information”. The problem lies in being “fully aware” of the root cause which was not the loose bolts, but the failure to detect and correct the problem, and more generally the state of inspection work and staff training. A related problem identified by the consultants was that previous repairs at the derailment site had created a weakness in the reaction rail which, combined with loose bolts, made the failure causing the derailment more likely.

The September presentation noted the difficulty of inspecting the reaction rail supports which required hands-and-knees posture to peer under the track in all manner of weather and lighting conditions. In practice, this level of inspection was rare because it was so difficult. Oddly enough, the Vancouver SkyTrain system uses a separate test, striking the support bolts with a tool, and listening for a dull “thud” instead of a clear “ping”. The “thud” indicates a loose bolt requiring closer inspection.

A common indication that there were problems is scuffing of the reaction rail. This was noted at several locations on the line. One does not have to peer under the track to see this early indicator of a developing problem. However, scuffing could also result from minor clearance problems with specific cars and this would not necessarily be interpreted as a location warranting detailed reaction rail review, especially if the marks had been seen repeatedly.

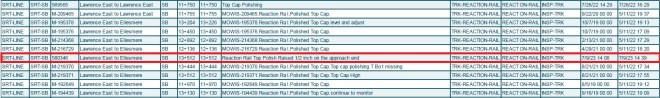

The most damning item is in the TTC’s own Maximo defect tracking system as reported by an inspection team two weeks before the derailment (July 9, 2023). The item highlighted below shows the reaction rail was “raised 1/2 inch on the approach end”. This was a defect serious enough to be visible without the usual difficulty of inspecting under the reaction rail. A related oddity is a two-week gap in reporting of any further problems leading up to the derailment.

In summarizing the investigation at the September meeting, TTC staff stated that the “immediate cause” of the derailment was the failed anchor bolts. Further, the consultants had recommended that if the SRT were to resume operation through November, then all of the newer bolts installed from 2016 onward should be tested and retrofitted as necessary. This work would have required “time well beyond the planned closure date”, and so the line remained closed. (See meeting recording.)

The estimated scope of this work implies a pervasive problem that was either undetected or whose potential severity was not understood, or worse ignored.

An important distinction here is that the term “immediate cause” has morphed into “root cause”. No matter the frequency of track inspections, the loose bolt problems would not be detected because they were not visible.

A further concern is the manner in which consultant reports were quietly posted on the TTC’s website with no announcement in November and December 2023. My coverage of them was the first that some TTC Board members I have spoken with knew about them.

The documents are posted under the Projects page for the future of Line 3 SRT replacement service, hardly a location one would look for technical info on the derailment. Three of the reports were posted in mid November and one in December. It is easy to verify that they were not there earlier by looking at Internet archives for the page on October 2 and December 7, 2023. The first three reports went up almost two months after the Board meeting, not “a few weeks” as expected. However, there was no media release about them nor were they brought to the Board’s attention.

At the September meeting, Councillor Matlow asked whether there could have been a reduction in maintenance or negligence due to the anticipated shutdown of the line. The Gannett-Fleming consultant replied that there were multiple possible causes for the bolts coming loose, but did not address the frequency of inspections.

Staff and consultants reiterated that inspections for problems of loose bolts were very difficult and they would generally not be spotted. It would not matter how often a walking inspection passed potentially defective reaction rail mounts because these were not visible. Indeed, there was an inspection on the morning of the derailment that found no issues.

The Network Rail consultant mentioned marks on the reaction rail surface in passing, but then talked about the impossibility of seeing bolt problems because they are under the reaction rail, and movement was seen only with a train passing. He also said that issues were being reported and fixed, but this is contradicted by the Maximo logs which show a reaction rail lifted 1/2 inch at the site two weeks before the derailment (see above).

One major problem with the Maximo records is that there is no explicit log of repairs made in response to problem reports. Moreover, the consultants noted that almost all issues were logged with a relatively low priority for repairs. I attempted to FOI the repair work orders. However, the TTC advised that the only record was that a defect report was closed, and that there was no information on the actual repair work. If true, this makes post-incident review of the nature of repairs, if any, impossible.

In September, Matlow asks whether there was an increase in maintenance on the aging system. Staff replied about the 2016 plan to replace the anchors which was well-intentioned, but as we know from the reports there were design and installation issues that eventually caused the failure.

Councillor Holyday pursued the anchor design issue. The replies mentioned that there were other locations with scuff marks but mostly from different causes. There was no mention of a problem, flagged by consultants, of repairs that created a weak spot due to cuts in both layers of the reaction rail at various points including the derailment site.

Matlow asked CEO Leary about how the TTC will prevent another accident, and Leary talked briefly about changes already underway and lessons learned. He then mentioned a planned November report, but this was the unfunded capital projects report, not a more detailed SRT report.

Leary pivoted to the Line 2 trains and signal system, and funding problems that could lead to shutdowns. He explicitly mentioned avoiding having old vehicles in service in the future. This ignored his original support for rebuilding Line 2 trains for a 40-year lifespan, and of keeping conventional signals because ATC would have been incompatible with these trains. Now he has changed his position.

The April 2024 Report

The April 2024 report goes to some lengths to establish that issues flagged by the consultant, Systra, who performed the peer review of other studies, were not germane to the derailment.

For reference, here is the Systra text:

The following key elements were deemed to be contributing factors:

• Data migration from MOWIS to MAXIMO: From the on-site contacts held with different stakeholders, the defects data has dropped off in number during the migration to MAXIMO, possibly due to the erasing of duplicated defects already present in MOWIS which may have artificially increased the number of defects prior to 2022. Overall, the migration process is not clear and should be reviewed and better documented. A detailed forensic investigation of this data migration was not possible as we did not witness this process.

Systra Report at p 1

• New anchor bolt design: Several aspects of the new anchor bolt design are questionable and could have led to the fatigue failure in the threaded portion which is very difficult to detect by track patroller.

• Reduction of preventive maintenance: Some actions linked to preventive maintenance were no longer carried out once the line was announced to be closing. Furthermore, the anchor bolts were never subjected to preventive maintenance.

• Top cap painting: The top cap was no longer re-painted making it was more difficult for track patrollers to detect new areas of “Polished Top Cap”.

• Training of track patrollers: The NRC report shows that the experience of the track patrollers is low, 11 out of 36 received their certification in 2021 and 17 are in the process of obtaining theirs. Track patrollers without their certification are required to patrol with a certified track patroller.

• Priority level: The priority level assignment for each defect is problematic since in the absence of standardized criteria, it implies a subjective interpretation from the track patroller. Also, each defect is evaluated individually, and the combination of defects is not considered in assigning a priority level.

• Reaction Rail height measurement: RC&S explains that the SRT Laser Inspection Train test was implemented approximately ten years ago, and the intent was to supplement proper reaction rail height inspections performed by Track and Structure, and not to supersede them. In our opinion, the periodicity is too long, it should be aligned with the inspection carried out on the rolling stock for the height of the LIM.

Systra did not present these issues as an hypothesis, but rather as “contributing factors”. The TTC responded in April with:

One of the concerns pointed out by the aforementioned Systra’s validation report was a reduction in defect reporting on the SRT reaction rail, from 2021 to 2023, citing a decrease in preventative maintenance. The TTC acknowledges that there was a decline in reported defects on the overall SRT line. However, there is no evidence to suggest that the TTC ever reduced any maintenance activities on the SRT due to the February 2021 announcement of the line closure. On the contrary, as previously demonstrated, after the announcement, the TTC continued to increase the reaction rail height survey throughout 2021 to address any reaction rail geometry issues.

TTC Report p. 7

However, simply looking at the reaction rail height will not reveal whether the support bolts are loose unless this is done under active load from motors of a train passing along the line. This effect is quite clear in the video displayed as part of the September 2023 staff presentation.

In the April 2024 report, the TTC cites the ongoing number of “track level activities” as an indicator of the level of maintenance.

However, it is not clear that an “activity” corresponds to maintenance work, especially if visual inspection could not catch problems with reaction rail bolts. Moreover, Systra’s point was that with the end of major capital repairs on the SRT, the only ongoing check on the infrastructure was the regular visual inspection which would not have detected bolt problems.

The problem with data migration from the old MOWIS system to Maximo was raised as a possible explanation for the statistics before 2022. This explanation vanished in the TTC’s April report.

With the review of all available records, the reason for the overall reduction in SRT reaction rail defects in 2022 is very much related to the improved reliability of the system assets and under no circumstances did the TTC decide to reduce maintenance on the SRT.

TTC Report p. 9

This directly contradicts Systra:

12.1 REDUCED TRACK MAINTENANCE

One of the effects of the closure of the line was the reduction of the capital project investments planned on the line, which is typical during such events. However, the various stakeholders interviewed confirmed that this had no impact on corrective maintenance.

Furthermore, with the reduction of capital project investment this also meant that the reaction rail was no longer maintained in a preventive way leaving only the 72 hours track patrols to detect any potential issues.

Systra report p. 16

As discussed earlier, the visual inspection every 72 hours would not detect problems with loose bolts even though this was a known issue with the reaction rail.

A reaction rail height survey would pick up out of alignment track such as the case with the July 9, 2023 defect report, but deflection caused by loose bolts would not be seen in a static review as opposed to one under actual operating conditions with full LIM attractive force on the reaction rail.

At no point in either the September 2023 presentation nor in the April 2024 report is the defective design and installation using Hilti anchors mentioned. This is key on at least three counts.

- The manufacturer did not intend for their system to be used in a configuration where the bolt would flex outside of its mount in the trackbed. This contributed to stress fatigue in the bolts.

- The bolts used were not the ones supplied by the manufacturer (which were too short) and the bolts substituted by the TTC had an incompatible thread that did not engage properly with the mounts.

- Post-derailment inspection showed that some mounts were not properly installed leading to a weakness in the bond between the mount and the trackbed.

These anchors are not intended to be used in bending load as it is the case on the SRT Line 3. The metallurgical analysis confirmed that this fracture was due to cyclic loading, hence failed in fatigue probably over a long period. Combining this with the inspection process of the track patroller of walking over the reaction rail during revenue service hours suggest that this failure was not systematically reported due to its difficulty to detect. It is possible that the condition of these new anchor bolts became worse over the last few years and was not detected by the track patroller given their inspection method.

Systra Report p. 18

The description of training levels of track patrollers differs between the Systra report and the TTC’s April response. Systra raises concerns about junior staff doing the work and having to patrol as under the supervision of a more senior colleague. The TTC claims:

[…] Systra […] stated that the TTC staff are fully aware of their roles, tasks, and commitments. It is worth noting that although NRC identified some new Patrollers who graduated in 2021, all TTC Track Patrollers who were fully certified met the APTA definition of a qualified person, which highlights that the Patrollers are considered competent as they all had at least two years of related experience.

TTC Report p. 9

The key phrase here is “who were fully certified”. The consultant’s point was that some patrollers were not certified. In effect, the TTC and their consultant are using different metrics of what constitutes a “qualified” patroller. This is troubling considering that, from other sources, I have learned that retention of staff in this position is difficult due to work hours and conditions. Turnover leads to junior staff who regardless of any training do not necessarily have two years’ experience as patrollers.

A related problem flagged by consultants is that actual track maintenance experience is needed to properly understand what an inspection should look for. This is difficult if the patroller position is seen as a stepping stone to a job with better conditions.

The TTC further states:

[…] Systra also indicated that corrective maintenance was carried out efficiently and on time […]

TTc Report p. 9

In their FOI reply, the TTC claimed that no work orders exist to document actual repairs. If so, it would be difficult to verify alleged repairs against the actual track conditions on and after the derailment date.

The TTC does not address the priority levels of defect reports, even though consultants observed that the ranking requiring immediate repairs or even a line shutdown (priorities 2 and 1) were almost never used. The July 9, 2023, report of a high reaction rail was filed as low priority, and it is clear from the condition of bolts at the derailment site that they had not been repaired.

The TTC report goes into some detail about the organization’s evolving asset management program for track up to 2024. While this is commendable, the best program and tracking system are only as good as the data fed into them. We know that the SRT visual inspections did not and could not pick up reaction rail bolt faults. A similar problem exists in the subway where there are limits to visual inspections and other means must be used to detect incipient track issues.

The recent flurry of subway slow orders arose because track geometry testing identified many areas requiring repairs. The TTC has increased the frequency of such tests to avoid a repeat of the situation in early 2024.

The consultants recommend that senior staff get out into the field often enough to verify the condition of the system and understand the problems faced by those who maintain it. No amount of desk review of asset management reports can substitute for seeing actual conditions.

In summary, the TTC’s April 2024 report makes considerable effort to detail changes in organizational procedures and asset management. This work is commendable especially if future disruptions of subway service and potential safety issues can be avoided. However, this deflects attention and acknowledgement from the fact that the SRT inspection methods did not identify emerging problems nor bring about timely repairs that could have prevented the derailment.

Appreciate all your articles. How about one on the Adelaide-York streetcar bypass delays. Supposed to be ready last year, still not…. Thx Paul

Steve: As previously the Adelaide-York delay was caused by Metrolinx who were slow off the mark with their portion of the project. This has been known since community briefings last year. Track and overhead work is now underway, and I will visit the project to get fresh photos next week.

LikeLike

Mr. Munro, your report is just scratching the surface.

You should investigate how TTC is contracting out maintenance and how that is turning out. Let me tell you that the results aren’t good.

Steve: Unfortunately, the results of the contracting out are not the subject of a detailed, published analysis. Unless the Board demands a truly independent investigation, something which has been unlikely for years because contracting out was seen as a money-saving tactic, we are not going to learn much.

LikeLike

I find it disingenuous and misleading to compare the tests on the SRT to the Vancouver Sky Train. The linear induction reactive rail is unique to the SRT and the Detroit People Mover. Vancouver has a standard third rail feed to rotary axle motors, just like the Toronto subway system among others.

Steve: That is true only of the Canada Line. The other Skytrain lines use the same propulsion system as Toronto’s. Indeed, at one point, Toronto was considering buying used cars from Vancouver to supplement the SRT fleet

This is not a misleading comparison at all. You might want to check your facts. It is trivially easy to pick up photos and technical descriptions of the system online.

LikeLike

It might be time for TTC to make their maintenance data and ongoing track analysis (photo’s, tickets, scans, etc.) public. It would be great as a public owner of the system to have a “street view” type system of all the infrastructure, close up and with full documentation…we see what the TTC leadership sees…

LikeLike

Steve.

Many of my friends in the Bus Maintenance division, at several bus divisions as well as operator friends, have long complained about the substandard attitude towards quality control, as per inspections, staff knowledge, maintenance being told to allow buses on the road (at certain divisions) that really shouldn’t be, aren’t safe in their opinions & even drivers have commented on serious issues they come across, reported & get the same bus days/weeks later, with the issues not resolved.

My friend who was driving today, had a bus that couldn’t do sharp right turns, literally could not do the tight turns needed at Royal York station, and it’s an 81xx series bus! They had to back up or do extremely wide turns to access the platform or have ppl board on the driveway.

This is not the first time.

The lack of detailed analysis of vehicles since Leary has been at the helm, has only gotten worse.

This has been told to me, countless times by ppl actually driving TTC vehicles.

I’m so angry about the line 3 incident, it was a damm miracle that no one in a wheelchair was on that train.

E.

LikeLiked by 1 person