In a previous article, I wrote about problems with the TTC’s subway work car fleet that were revealed by a day-long shutdown of Line 2. See The State of Disrepair (II).

A series of question to the TTC brought little information and a reply suggesting my sources did not know what they were talking about when, in fact, the TTC misrepresented my question.

TTC management have not yet reported to the Board on the status of the work car fleet.

Updated: There is a one-page status update in the June 20, 2024 Board Meeting agenda in the CEO’s Report.

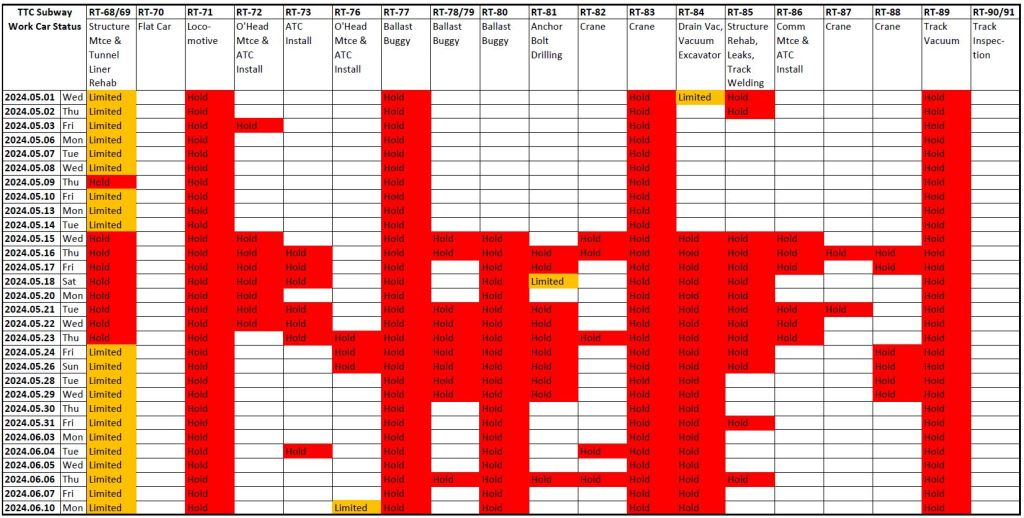

Work car condition and availability are key to the large off-hours program of infrastructure renewal. Many of these cars are specialized for their tasks and, unlike the passenger fleet, cannot be substituted for each other. The variety is shown in the chart below which was part of a TTC presentation at the May 2024 board meeting.

Immediately after the hydraulic fluid leak on May 13, much of the fleet was put through an inspection to determine how prevalent leaks and similar problems might be. Until they were deemed fit, cars that could have such problems were out of service. The sudden change in availability is shown in the charts below.

The red cells indicate that a car was held out of service either for repairs, or awaiting inspection. The amber cells indicate a car that can be used with some restrictions depending on the fault. On Wednesday, May 15, two days after the Line 2 shutdown, much of the fleet was put on hold for inspection with cars gradually returning. Details about individual cars follow later in the article.

This information is taken from daily reports of the work fleet’s status. Note that some days, mainly on weekends, are missing. Each page below covers the six-week interval for a group of cars.

Of particular concern are the two tie-tampers, RT-21 and RT-41 which are crucial for some major rail work. Both have been out of service since mid-May, and projects are rescheduled to work around the availability of needed cars.

There is a direct link between the availability of work cars and the TTC’s ability to keep up with ongoing maintenance, let alone to address a backlog. Scrimping on the budget for maintenance vehicles might solve a short term budget problem, but it exposes the system to disrepair through just getting by with available resources.

Status of Subway Work Cars

The information here summarizes the Daily Workcar Reports. I have included this level of detail for those who are interested in the variety of problems, the number that were found in mid-May by the inspection blitz, and the amount of work still outstanding.

In some cases cars are held out of service for a short period for a scheduled inspection that might find no problems. By contrast some cars are out of service for extended periods awaiting inspection or repairs.

In case you’re wondering, this information came my way from a trusted source.

Legend

- APU: Auxiliary power unit

- ATP: Automatic train protection (provides location information to automatic train control system)

Flat Cars

These are simple vehicles that generally do not show up in “hold” status:

- RT-01, RT-02, RT-47, RT-57, RT-58, RT-70: No holds

- RT-42: Held on May 3 for standard inspection

Tunnel Leak Repair

- RT-05:

- Held on May 6 with propulsion problems

- Tested OK on May 8

- Held for same problems on May 9

- Returned to service on May 23 following repairs

Drain Vacuum Excavator

- RT-06:

- May 1-14: One axle not powered, restricted to emergency mode (no ATP), other minor issues

- May 15-June10: Held: Multiple small leaks found

- RT-46

- May 1: Cracked odometer bracket on truck frame, restricted to emergency mode (no ATP)

- May 16: Held for inspection.

- May 17: Multiple small leaks found.

- May 29: Returned to limited status.

- RT-56

- May 2: Limited use: Waste tank leaking.

- May 6: Held: Waste tank leaking. Major repairs required.

- May 10: Repaired. OK for service.

- May 13: Held: Major oil leak under car.

- May 15-June 10: Held: Oil leak plus hydraulic inspection pending.

- RT-84

- May 1: Limited use: Water system leaks.

- May 2: Repaired. OK for service.

- May 15-June 10: Held: Hydraulic inspection. Several problems found. Parts on order.

Track Vacuum

- RT-89

- May 1-30: Held: Engine overheating. Waiting for parts.

- May 31: Held: Repaired and OK for service.

- May 15-June 10: Held: Waiting on hydraulic inspection.

Locomotive

- RT-07

- May 15-June 10: Held: Multiple leaks, transmission oil under car, compressor leaks. Parts on order.

- RT-18

- May 13-14: Limited: Transmission sluggish.

- May 15: Replaced broken brake cylinder. Inspected for leaks, none found. OK for service.

- May 16: Held for hydraulic inspection.

- May 17: Inspected OK.

- May 29: Hold for hydraulic inspection.

- May 30: Inspected OK.

- June 6: Hold for hydraulic inspection.

- June 7: Inspected OK.

- RT-71

- May 1-June 10: Hold: Dead batteries.

Rail Delivery

- RT-08: No holds

Ballast Delivery and Buggies

- RT-40:

- May 15-16: Hold: Hydraulic inspection found leaks. Replaced alternator.

- May 17: Tested OK.

- May 21-23: Hold for hydraulic inspection.

- May 24: Inspected OK.

- May 28-29: Hold for hydraulic inspection.

- May 30: Inspected OK.

- June 6: Hold for hydraulic inspection.

- June 7: Inspected OK.

- RT-77

- May 1-June 10: Hold: Cracked suspension element. Replacement on order.

- RT-78/79

- May 15: Hold for hydraulic inspection.

- May 16: Found leaks.

- May 17: Tightened fittings. Inspected OK.

- May 21-29: Hold for hydraulic inspection.

- May 30: Inspected OK.

- June 6: Hold for hydraulic inspection.

- June 7: Inspected OK.

- RT-80

- May 15-18: Hold for inspection. Hydraulic filter to be replaced. Parts on order.

- May 20-June 10: Hold: Leaks under distribution blocks. Parts still on order.

Structure Maintenance & Tunnel Liner Rehabilitation

- RT-09/10:

- May 16-18: Hold for hydraulic inspection. Some parts replaced. Tested OK.

- June 6: Hold for hydraulic inspection.

- June 7: Tested OK.

- RT-30/31:

- May 15-21: Hold for hydraulic inspection.

- May 22: Replaced parts. Tested OK.

- May 29: Hold for hydraulic inspection.

- May 30: Tested OK.

- RT-32/33:

- ATP installation in progress. Hydraulic inspection pending.

- RT-38/39:

- May 15-16: Hold for inspection. Leaks found.

- May 17: Parts replaced. Tested OK.

- June 6: Hold for inspection.

- June 7: Tested OK.

- RT-60/61:

- May 15-20: Hold for inspection. Found leaks.

- May 21: Parts replaced. Tested OK.

- June 6: Hold for inspection. Water leak on window of RT-60.

- June 7: Repaired and tested OK.

- RT-62/63:

- May 15: Inspected. No leaks found.

- May 16-20: Hold for inspection.

- May 21: Replaced hoses. Tested OK.

- June 6: Hold: APU belts need re-tensioning.

- RT-64/65:

- May 15-22: Hold for inspection. Found leaks.

- May 23: Tested OK.

- May 29: Hold for inspection

- May 30: Limited to electric use only.

- June 3: Repair completed.

- June 6: Hold for inspection.

- June 7: Inspected OK.

- RT-66/67:

- May 15-20: Hold for inspection. Found leaks.

- May 21: Part replaced. Tested OK

- June 6: Hold for inspection.

- June 7: Inspected OK

- June 10: Limited: Electrical mode only.

- RT-68/69:

- May 1-June 10: Car in limited or hold status. Inverter not working, removed for repair. Car OK in electric mode only. APU engine major coolant system leak. Parts replaced, some on order.

Structure Maintenance Leaks and Track Welding

- RT-85:

- May 1-2: Hold: Controller problems. Cracked windshield.

- May 3: Replaced inverter and voltage regulator. Tested OK. Windshield on order.

- May 15-26: Hold for inspection: Leak found.

- May 27: Inspected OK. Windshield still on order

- May 31: Hold for inspection. OK.

- June 6: Hold for inspection.

- June 7: Inspected OK.

Tunnel Liner Repairs

- RT-29: No holds

Crane

- RT-11:

- May 15: Limited: Reels out of service (ongoing problem). Air leak under deck. Lubricated seized rod for brake release valve.

- May 16: Hold

- May 17-21: Limited. Hydraulic inspection OK.

- Mar 22-23: Hold for inspection.

- May 24-28: Limited: Inspection OK.

- May 29: Hold for inspection.

- May 30-31: Limited. Hydraulic inspection OK.

- June 3-4: Hold for inspection.

- June 5: Limited: Hydraulic inspection OK.

- June 6-10: Hold: Reels still out of service. Remote control issue: left-right reversed.

- RT-20:

- May 15-June 7: Hold for inspection. Leaks found.

- June 10: Repairs completed.

- RT-28:

- Limited May 13-14: Engine coolant leak. APU shuts down.

- May 15-June 10: Held for inspection and repair.

- May 30: Engine seals repaired.

- RT-55:

- Out of service due to collision with RT-83 and extensive damage.

- RT-82: Hold M15-16 / H M23 / H J4 & J6 / J7 RI ok

- May 15-17: Hold for inspection. Leaks found.

- May 17: Repairs completed OK.

- May 23: Hold for inspection. Crane not working properly.

- May 24: Hydraulics OK. No problem found with crane.

- June 4: Hold for crane issues. No problem found.

- June 6: Hold for inspection.

- June 7: Inspection OK.

- RT-83:

- Out of service due to collision with RT-55 and extensive engine damage.

- RT-87:

- May 16: Held for inspection. Crane not working properly. Repaired and tested OK.

- May 17: Inspection OK.

- May 21: Found leaks.

- May 22: Repaired and tested OK.

- RT-88:

- May 16-17: Held for inspection. Leak found.

- May 24-28: Held for inspection.

- May 29: Inspection OK. Replaced APU power supply and blown fuses.

Asbestos Removal

- RT-13-15: No holds.

- RT-34-36:

- May 17: Limited

Tunnel Washer

- RT-16:

- May 15-24: Hold for inspection. Found leaks

- May 28: Disabled at Keele Yard. Hydraulic inspection OK.

- RT-17:

- May 16-June 2: Hold for hydraulic inspection.

- June 3: Inspected OK.

- June 4-10: Hold for standard inspection.

General Utility

- RT-19:

- May 15-23: Hold for hydraulic and standard inspection.

- May 24: Repairs completed.

Tie Tamper

- RT-21:

- May 15-June 10: Hold for hydraulic inspection. Found leaks.

- RT-41:

- May 1: Hold. No propulsion.

- May 2: Repaired broken wire.

- May 7-8: Hold: Oil leak at pump.

- May 9: Pump replaced.

- May 16-June 10: Hold: Hydraulic leak found.

Overhead and Communications Maintenance, ATC Installation

- RT-25:

- May 14: Limited. ATP working intermittently (ongoing problem).

- May 15-19: Hold for inspection:

- May 20: Wet pressure line.

- May 22-June 4: Pump replaced. Limited use due to ATP issues.

- June 5: Hold for inspection.

- June 6-10: Inspection OK. Limited use continues.

- RT-72:

- May 3: Hold: Flat wheels. Wheels turned.

- May 15-22: Hold for inspection. Found leaks.

- May 23: Reinspected OK.

- RT-73:

- May 16-18: Hold for inspection. Repaired.

- RT-86:

- May 15-17: Hold for inspection. Found leaks.

- May 18: Repaired OK.

- May 21: Hold for inspection.

- May 24: Inspection OK.

PEV Beam Replacement

- RT-27:

- May 15-June 5: Hold for inspection. Found leaks.

- June 6: Repaired OK.

Snow Throwers

- RT48-53:

- May 15-June 10: Hold for inspection (seasonal)

Anchor Bolt Drilling

- RT-81:

- May 16-29: Hold for inspection. Other repairs pending.

- May 30: Reinspected OK.

Track Inspection

- RT-90/91: No holds

Nothing to see here. Move along.

LikeLiked by 1 person

That’s a pretty amazing report and shows how TTC have clearly ignored the work fleet – for years. I guess the offer of unveiling a new Tie Tamper does not get them many points with Councillors! The more one (i.e. YOU, Steve) drills down into the detail the worse the TTC looks.

LikeLiked by 1 person

There’s also a significant amount of disrepair that endangers many bike riders along the edges of the trackbed concrete, not merely the rails themselves. The City helps out by not counting any injuries from tracks in any counting up of cycling injuries though the deaths are harder to ignore. Of course this is mostly all in the older core, and alas, the other options for some of the main roads just don’t exist eg. Queen out and in to Parkdale.

LikeLiked by 1 person

Ignoring maintenance is an easy substitute for brains when the people at the top have no long or medium term interest in the organization they control.

LikeLike

Yes, the concrete ‘margins’ of the streetcar tracks (between rail and asphalt) never seem to be properly maintained. One would have thought that an annual program to repair these along all TTC streetcar routes would pay off in reducing damage to rail plus, of course, being much safer for cyclists and other road users. But ….

Steve: A problem here is the split responsibility for road maintenance between the City and TTC on streetcar streets.

LikeLike

This is *abhorrent*.

wow.

LikeLiked by 1 person